American vs. European windows: differences that matter for your business

Choosing between U.S. and European windows isn’t about style or trends. It directly affects your project cost, construction risk, and schedule.

In this article, we break down the real differences between American and European windows that matter to U.S. builders.

Where European windows can save money, where they introduce risk, and when sticking with U.S. systems is the safer choice.

Table of contents:

- USA vs Europe – installation differences

- Price comparison

- Differences in construction

- Custom windows

- Projects’ Gallery

- What changes when switching to European windowsropean windows

Quick takeaway for U.S. spec home builders

European windows work best when: |

American windows are better choice when: |

|---|---|

projects involve high-end or custom homes |

delivery time is more critical than unit cost |

window dimensions are finalized early |

projects are fast-track |

cost optimization matters more than speed |

late-stage changes are common |

USA vs Europe – installation differences

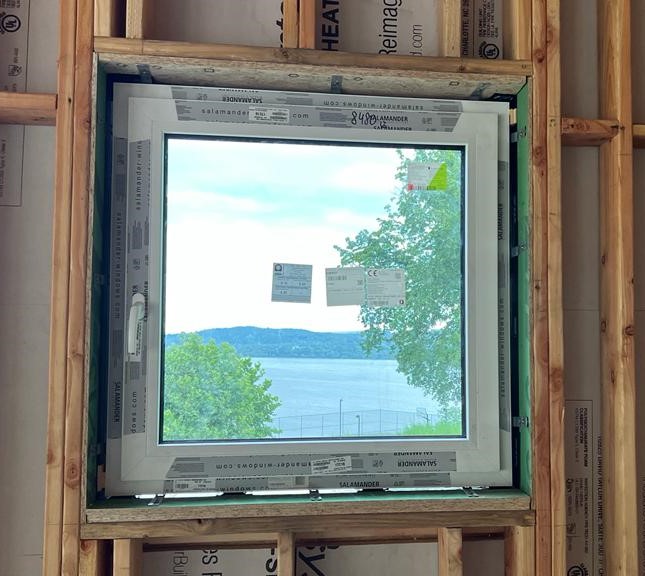

European window installation is not a technical risk – it’s a learning and planning consideration.

European windows can be installed either flangeless or with a nailing fin (some EU manufacturers offer flange options).

To help you decide which option fits your project best, read our installation strategy overview.

For crews new to European systems, we also provide a step-by-step guide to flangeless European window installation.

What are main differences between US and EU window installation?

American windows are nailed into the opening, while European windows are attached to the wall along the perimeter using brackets and anchors. The process is quite simple, although there are a few things to remember when installing European windows:

- ✅ European windows are heavier than American ones, so this is definitely a two-person installation job (or more). Always check the exact weight on your invoice specifications.

- ✅ European windows require more precision during installation.

- ✅ After proper installation, European windows don’t leak and can withstand decades of use.

Real-life tips from U.S.-based installers experienced with European windows

Install? Not a problem. It’s about the same as American windows. If you’re experienced, you’ll handle it.

The only real challenge was the weight – these windows are just much heavier than typical American ones.

But to me, that also means better quality. More material, more solid build.

The difficulty level of installing European windows is different; they are heavier than American ones and require more precision.

However, in the end, if I can pay less and get better quality, I choose windows from Poland over American ones.

Switch from U.S. to European windows safely

Choose European windows over American and save up to 50%

while getting higher-spec units, so homes show better and sell faster.

See dedicated offer for:

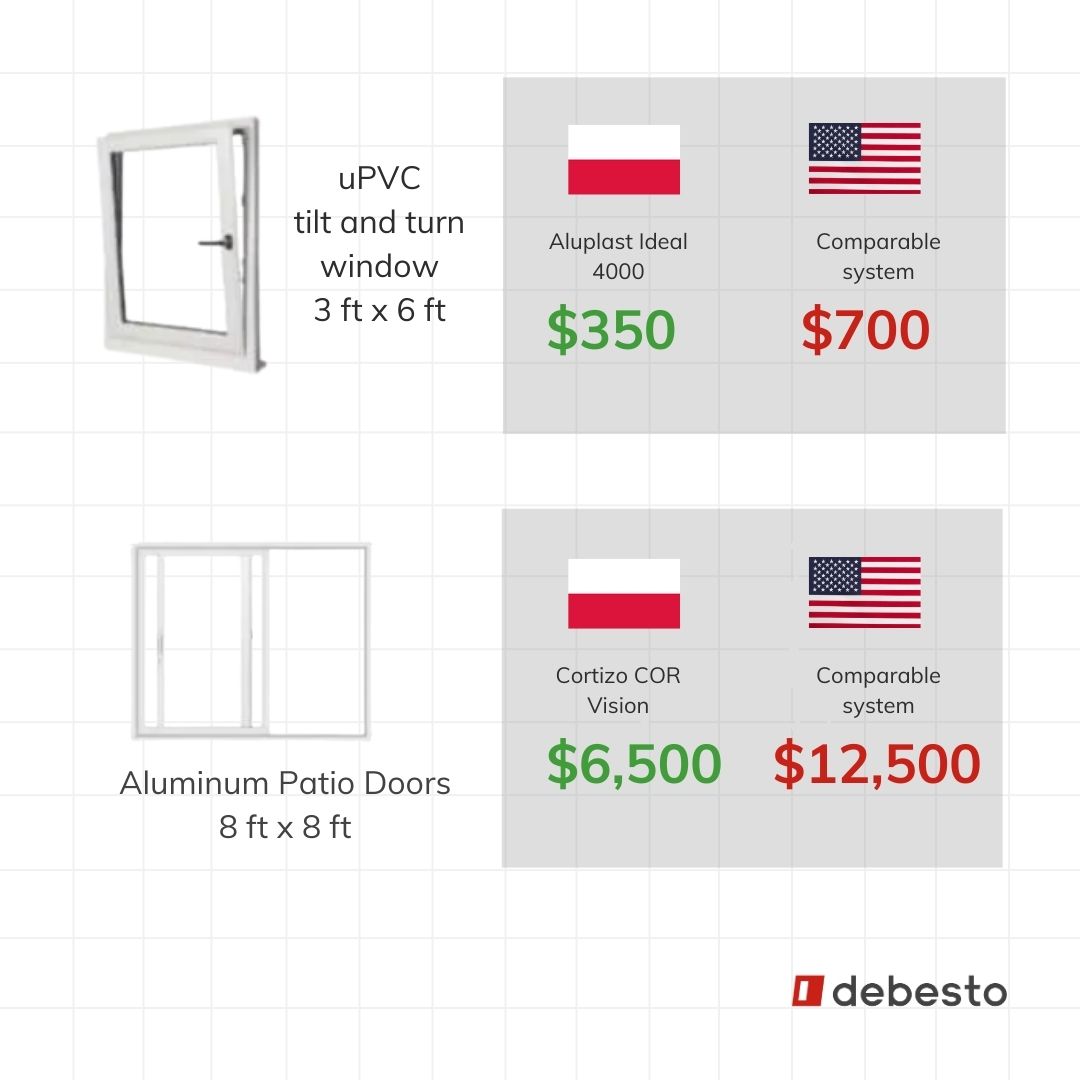

USA vs EU – Price Comparison

Real-life example: $150,000 US dealer quote vs European windows total landed cost (delivered): $99,750

Here is the breakdown:

- Window Production: $75,000

- Shipping: +$6,000

- Duty: +$18,750

👉 Net Savings: $50K extra margin on this project

Prices as of January 2026. Based on debesto internal data from Polish suppliers.

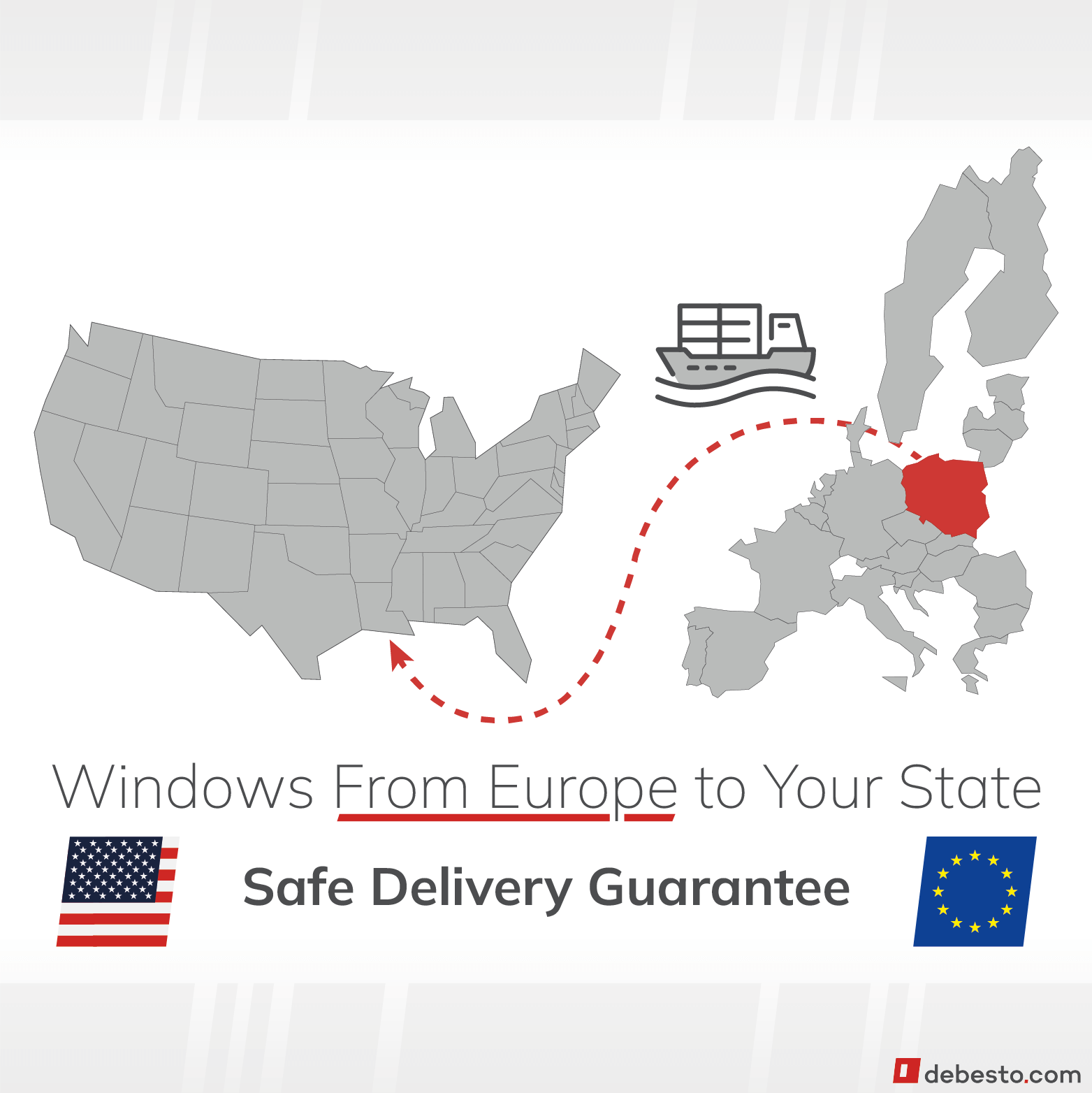

European windows are even up to 40-50% cheaper than American ones, without compromising on quality.

There’s probably a catch here, right? Not really. European windows are more affordable for several reasons, especially when imported directly. Even after Trump’s tariffs.

Why European windows are more affordable

- Automation – European manufacturers use highly automated and modern manufacturing processes.

- Scale – Thanks to large-scale production, Polish manufacturers can optimize costs. Poland is the world’s largest exporter of windows and doors.

- Borrowed technology – Polish manufacturers use advanced German technology, so they don’t need to invest resources in developing systems from scratch.

- Low production cost – Polish labor costs are several times lower than in the U.S.

See our price lists to explore more about prices for windows in Europe

US vs EU Windows – Construction Differences

Types of European windows:

- Tilt & Turn windows

- Sliding Patio Doors,

- HST – lift and slide patio doors

- PSK – tilt and slide patio doors

- SMART-SLIDE (very tightly sealed)

- Bifold doors

- Fixed Windows (same as picture window)

Types of American windows:

- Awning,

- Casement,

- Double Hung & Single Hung,

- Gliding / sliding

- Bay&Bow Window,

- Picture Window (same as fixed window).

European window materials:

American window materials:

- vinyl

- aluminum

- composite / fiberglass

- wood

Differences in window construction can affect job site schedule, costs, and risk. European systems are heavier due to steel reinforcement inside the uPVC profiles and solid glazing units.

Weight examples from the spec home window schedule:

- Sliding door, size 166 × 105 inches: 851 lbs (386 kg)

- Picture window, size 34 × 95 inches: 108 lbs (49 kg)

- Tilt-and-turn window, size 34 × 64 inches: 89.5 lbs (41 kg)

Custom windows in Europe

Looking at U.S. windows, you might assume their main advantage is standardization. It feels safer to buy standardized units because you know what you’re getting. In theory, they should also cost less. In reality, that’s not always the case.

In Europe custom is a standard, without extra charge

The advantage of European windows is that they are tailor-made.

Even if you find someone to make American windows to size, their quality leaves much to be desired, not to mention the extra cost.

You can use our uPVC window costs calculator to see within seconds what the prices of European made-to-measure windows look like.

What changes when you move from U.S. windows to European windows

Switching from U.S. to European windows has real consequences – not in product quality, but in coordination, timing, and execution.

Instead of buying from a local manufacturer, you’re working across markets, standards, and timelines.

That’s why the key risk is rarely the window itself. It’s more how specifications, logistics, and installation details are aligned between the factory and the job site.

In practice, successful projects rely on clear coordination between the builder, architect, and European manufacturer. With one point of contact responsible for keeping everything aligned.

This approach is already used on U.S. residential projects – see examples from recent spec home builds.

When European windows make sense for spec home projects and when not

In practice, European windows are most often used on spec home projects with cost control, custom sizing, and early coordination.

✅ They are typically chosen when:

- window budgets are under pressure and need optimization,

- architectural design goes beyond standard U.S. sizes,

- window dimensions can be finalized early and verified before production.

In these scenarios, European systems allow developers to balance unit cost, performance, and design flexibility. That can be significantly more expensive with U.S.-made custom windows.

❌ On the other hand, projects that rely on late-stage changes, loose framing tolerances, or fast-track schedules tend to stay with U.S. systems, where flexibility outweighs potential savings.

For a deeper look at project’s profitability see When imporitng windows from Europe makes financial sense – and when it doesn’t.

How debesto helps

debesto’s role is not just sourcing windows, but reducing execution risk for U.S. developers working with European systems. We coordinate specifications with manufacturers, support installation planning, and manage logistics so windows arrive on time.

Our process is designed to minimize back-and-forth, avoid late surprises, and give developers clear answers early enough to protect margin and schedule.

European or U.S. windows – what’s best for your project?

Not sure whether to choose windows from Europe or America? European windows aren’t always the best choice. We can consult on your project and help you decide which option will best support your business goals.

Book free project consultationFrequently Asked Questions

For New York, the typical lead time is 8 to 12 weeks. Before production starts, your window schedule must be reviewed and converted into a technical specification. Production usually takes 3 to 7 weeks, depending on the material and window type. Delivery to the East Coast takes about 5 weeks and longer for the West Coast.

The price includes system production but excludes duties. Insurance is included in the shipping and inland delivery costs, which you can estimate using our delivery cost calculator.

During the consultation, we estimate total costs for you, including production, tariffs, and delivery (with warranty and insurance included). Prices are fixed in the offer, so you won’t pay more than what’s agreed after the pro forma invoice.

In Poland, small size adjustments usually don’t affect pricing, since custom sizes are standard. Before production starts, we confirm all dimensions with you to make sure everything is correct.

Based on customer experience, average savings are around 40%, but this depends on project specifications. In some cases, cost optimization comes not only from unit price but from switching from low-quality vinyl to thermally broken aluminum systems.

Ocean transport is the least predictable part of the process. Port congestion or weather can cause delays, even with a solid shipping plan. However, with over 10 years of experience shipping from Poland to the U.S., we can estimate a realistic delivery schedule and include a buffer for your jobsite timeline.

This article was updated in February 2026