High-altitude windows: What you need to know about the glazing?

With buildings located high above sea level, there are specific considerations that need to be taken into account regarding high-altitude windows. Altitude can have a significant impact on the performance and durability of windows, particularly in relation to glazing.

In this article we will explore why special glazing might be necessary, as well as how to determine if it’s required, and what information you need to provide to ensure your windows are suitable for high-altitude installations.

Table of content:

- Why Altitude Matters

- Special Glazing Solutions for High-Located Projects

- Altimeters and Other Measurement Tools

Why Altitude Matters for Windows

As altitude increases, the atmospheric pressure decreases. Consequently, this change in pressure can affect the sealed air spaces within double or triple-pane windows, leading to issues like distortion of the glass panes or even breakage.

Moreover, the differential pressure between the inside of the window and the external environment at high altitudes can cause stress on the window unit, which is why special glazing solutions are often necessary.

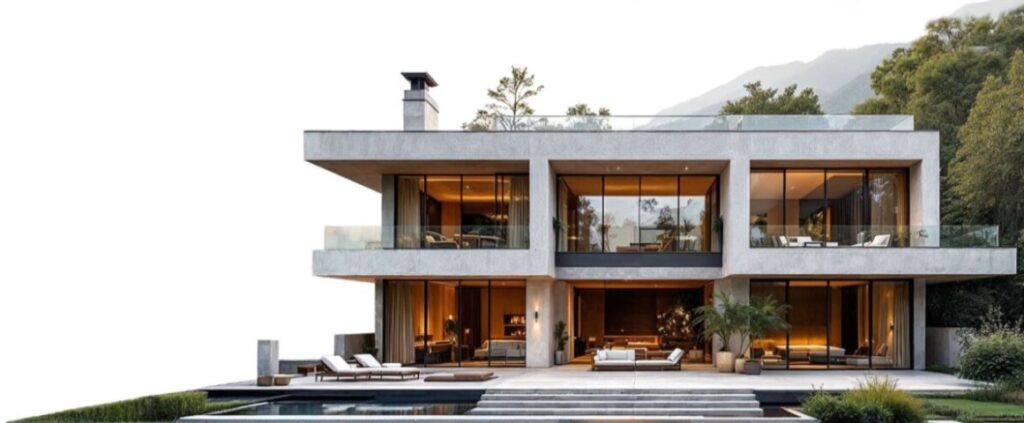

Upscale your spec home with high-performance windows from Europe

We manage the import process and help you find windows that

meet building codes, fit your deadlines, and boost your profit margins.

See dedicated offer for:

Special glazing solutions for high-altitude windows

In order to address the challenges posed by high altitudes, several solutions can be implemented:

- Breather Tubes: These are small tubes that allow the internal pressure of the window to equalize with the external atmospheric pressure during transportation and installation. Once the window is installed, these tubes are sealed to maintain the window’s insulating properties.

- Capillary Tubes: Similar to breather tubes, capillary tubes are used to equalize pressure. However, they are more commonly used in high-altitude installations. They can remain open without compromising the insulation, allowing for continuous pressure equalization.

- Gas Filling Adjustments: In double or triple-glazed windows, the space between the panes is filled with inert gases like argon or krypton to improve insulation. However at high altitudes, the gas filling might need to be adjusted or replaced with air to prevent distortion caused by pressure differences.

- Specially Designed Glazing Units: Some manufacturers offer glazing units specifically designed for high-altitude installations, where the glass thickness, spacer materials, and sealing techniques are optimized for low-pressure environments.

Altimeters and Other Measurement Tools

In order to determine whether special glazing is required for your project, you’ll need to gather specific information about the installation site. Therefore this data helps manufacturers adjust their products to ensure optimal performance. Here’s what you’ll need:

- Max Window Installation Height (meters above sea level): The altitude where the windows will be installed is critical for determining the pressure differential the window units will experience.

- Average Annual Temperature at the Installation Site: This helps in understanding the thermal expansion and contraction the windows will undergo, which can affect the glazing.

- Max Temperature in the Room: This data is essential to account for internal pressure changes due to temperature fluctuations.

- Average Temperature in the Room: Consistent internal temperature data assists in balancing the pressure considerations between the inside and outside of the window.

- Max Road Transport Height (meters above sea level): If the windows will be transported over mountain passes or through areas of high altitude, this could impact the glazing, The manufacturer needs this information to ensure that the windows can withstand pressure changes during transport without being damaged.

Use of altimeters

Altimeters are typically used during the survey and transportation stages to accurately measure the altitude of the installation site and along the transport route. This precise data allows manufacturers to tailor their products specifically to the conditions they will face, ensuring long-term performance and durability.

Summary

In conclusion, if the building is located at a high altitude, it’s essential to consider the impact of reduced atmospheric pressure on the windows. By doing so, you can mitigate potential problems.

Furthermore, by using special glazing solutions and providing accurate data regarding your site’s altitude and temperature conditions, you can ensure your windows will perform optimally and avoid issues like glass distortion or breakage.

Therefore, always consult with your window manufacturer or supplier to ensure you receive the best advice and products for your specific needs. Deepen your knowledge about offer from European and learn more about custom windows.

Need help with high altitude window project?

Do you need help with choosing right windows for project located high above sea level? We are ready to help you!

Book a project consultationFAQ

1. Do I always need special glazing if my building project is located at a high altitude?

Not always, but it’s highly recommended. The need for special glazing depends on several factors, including the altitude of your installation site, the type of glazing unit, and the potential for significant pressure differences between the inside and outside the window. Consulting with your window supplier can help you determine if special glazing is necessary.

2. What are the risks of not using special glazing at high altitudes?

Without special glazing, windows installed at high altitudes may experience issues such as glass distortion, seal failure, or even glass breakage due to the pressure differences between the internal and external environments. These issues can compromise the insulation properties of the windows and lead to higher energy costs and reduced comfort.

3. How do breather and capillary tubes work in high-altitude windows?

Breather and capillary tubes allow for the equalization of pressure between the inside of the window unit and the external atmosphere. Breather tubes are sealed after installation. Capillary tubes may remain open to continuously equalize pressure, preventing the risk of glass distortion or breakage.

4. Can I use standard double or triple-glazed windows at high altitudes?

Standard double or triple-glazed windows can be used at high altitudes, but they may require modifications, such as the addition of breather or capillary tubes, or adjustments to the gas filling. Without these modifications, the windows may not perform optimally and could be at risk of damage.

5. What information should I provide to debesto if I live at a high altitude?

You should provide the following information:

- The maximum height at which the windows will be installed (meters above sea level).

- The average annual temperature at the installation site.

- The maximum and average temperatures inside the room.

- The maximum altitude reached during transport of the windows (if applicable).

This information helps the manufacturer tailor the glazing solution to your specific conditions.

6. How can I measure the altitude of the building or installation site?

You can measure the altitude using an altimeter, GPS devices with elevation tracking, or by consulting topographical maps. Accurate altitude data is crucial for ensuring your windows are designed to withstand the pressure differences they will encounter.

7. Are there any additional costs associated with high-altitude glazing solutions?

Indeed, yes, there may be additional costs involved in modifying windows for high-altitude installations. Specifically, these costs typically cover the installation of breather or capillary tubes, adjustments to the glazing unit, and any specialized manufacturing processes required. However, these costs are generally outweighed by the benefits of preventing window damage and maintaining energy efficiency.

European Windows for Spec Home Builders

- Save up to 50% – Direct from Poland

- On-site Delivery – Seamless Import

- Installation Support Included

Check dedicated offer for: